Bring your corrugated starch adhesive robustness to a new level with Exilva MFC

Synnøve Holtan | May 26, 2020

In a previous blog post, I explained how the new technology of Exilva microfibrillated cellulose may improve the viscosity stability of starch adhesives. Here is the second blog post in the corrugated boards application series, and now I have entered the glue kitchen of a corrugated boards manufacturer to evaluate the robustness and stability effects of Exilva.

- You can find the previous post here; A way to reach prolonged stability of starch adhesives

Two adhesives were made from native wheat starch according to the Minocar process; one reference adhesive comprising 0.15% borax (Fullbor WB 6364, HB. Fuller), and one comprising 0.12% microfibrillated cellulose (Exilva PBX 01-V, Borregaard) in addition to borax. The Minocar process gives a two-phase adhesive: A primary starch solution (called carrier) of partially swollen starch granules, in which uncooked raw starch (secondary starch) is suspended.

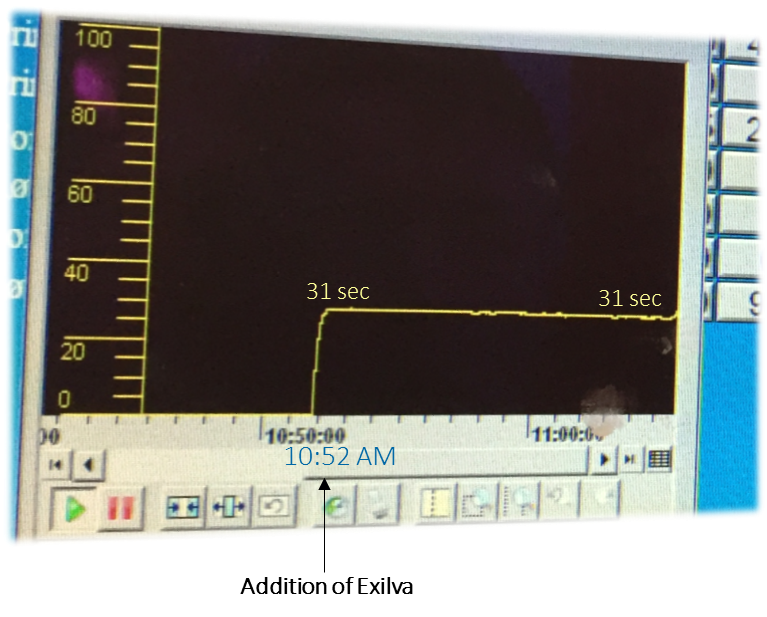

The carrier is prepared by the action of sodium hydroxide and heat on the starch slurry. The microfibrillated cellulose was added after the secondary starch; it was easily dispersed in the adhesive and stabilized the viscosity throughout the final 15 minutes of high shear mixing time (Figure 1).

Figure 1. Viscosity stability in manufacturing of adhesive upon addition of Exilva.

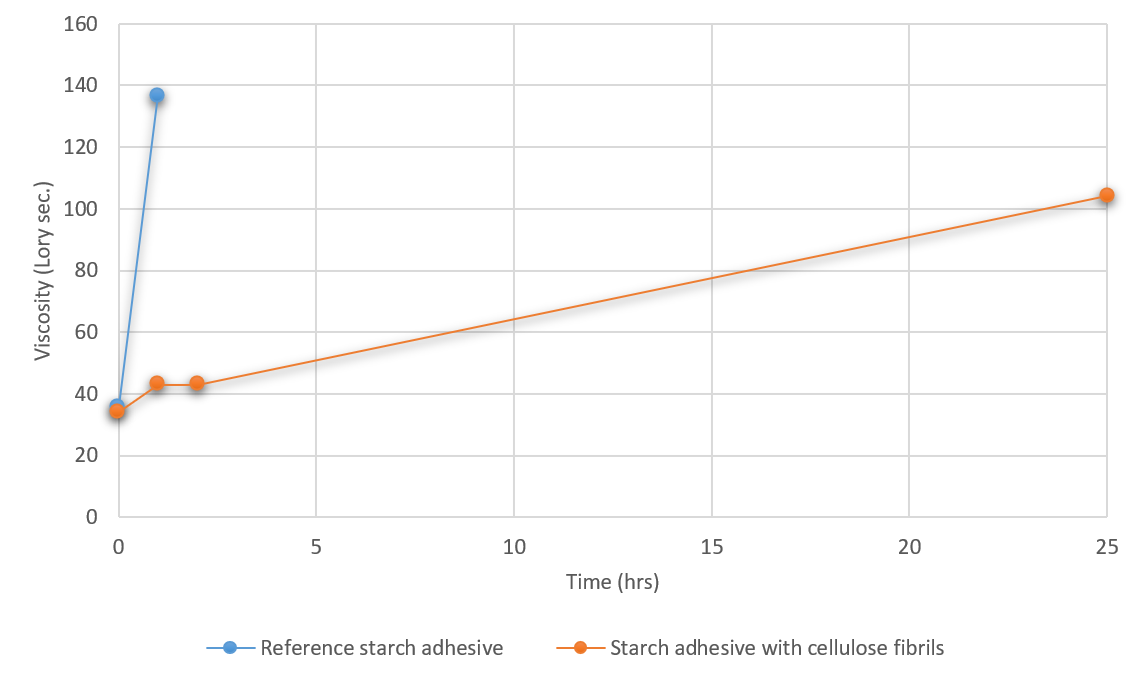

Both for the reference adhesive and the adhesive comprising Exilva, the viscosity was measured initially, and over time standing without stirring at 20°C, with a Lory viscosity cup (Elcometer 2215/1). The viscosity of the reference adhesive increased to critical level (137 Lory sec.) after 1 hour of storage at 20°C. In comparison, the viscosity of the adhesive with Exilva was only 43 Lory sec. after 1 hour, and still below critical level after 25 hours of storage at 20°C, see Figure 2.

Figure 2. Change in viscosity over time with Exilva microfibrillated cellulose added (orange) against the reference without Exilva (blue).

Storage stability in process tank

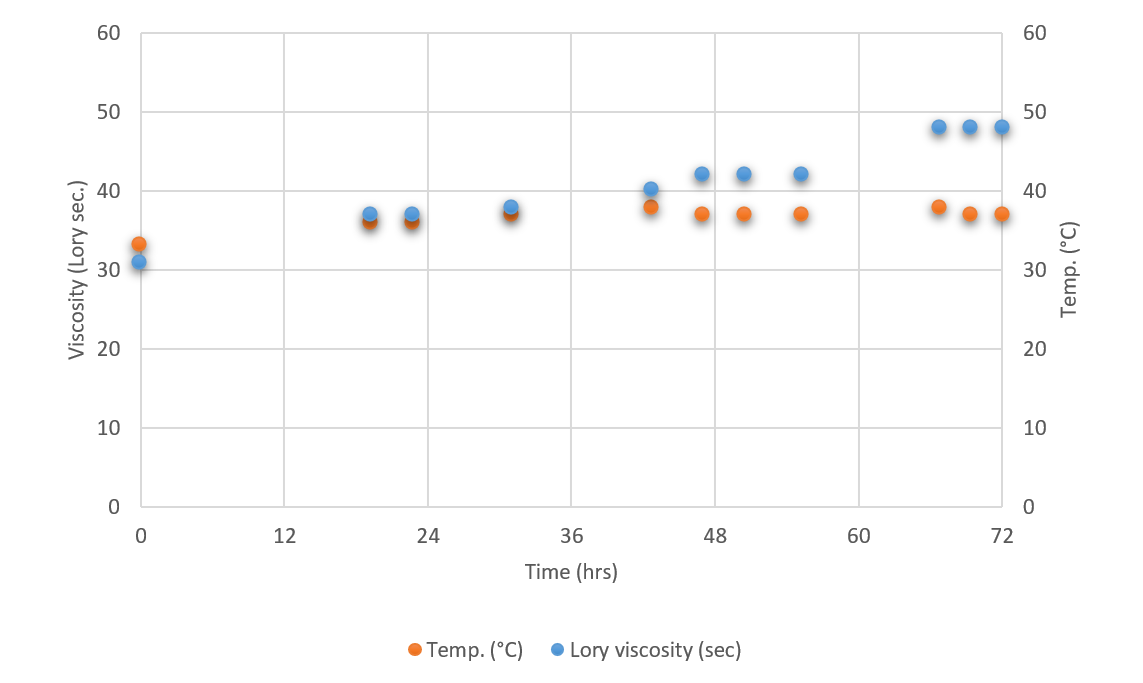

The Lory viscosity and temperature for the starch adhesive with Exilva were also measured over time in the full scale factory storage and process tank, see Figure 3. To prevent sedimentation during storage, the adhesives are normally stirred for 5 minutes every hour. With Exilva, the stirring frequency of the adhesive could be significantly reduced to stirring for 5 minutes every fourth hour. The viscosity of the adhesive was 48 seconds after 72 hours of storage and it could be used directly (without adding water) for the production of corrugated boards.

Figure 3. Change in viscosity and temperature of the starch adhesive comprising Exilva during storage in the factory adhesive tank. After 72 hours, the viscosity and temperature of the adhesive increased from 31 to 48 seconds, and from 33 to 37°C, respectively.

The reason behind the stabilizing effect

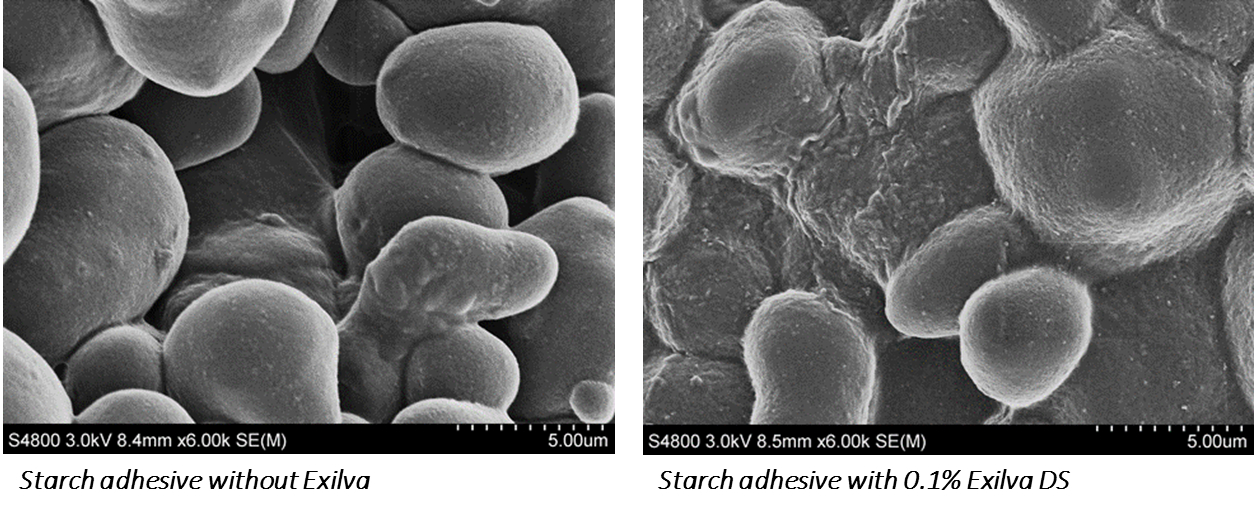

The highly entangled network of Exilva microfibrillated cellulose constitutes a large surface area, which enables a strong interaction with starch by multiple hydrogen bonding. This three-dimensional network formation seems to stabilize the cooked starch towards retrogradation, and furthermore to stabilize the raw starch granules preventing them from sedimentation, and possibly restrain swelling (Figure 4 ).

Even at low viscosities caused by a bacterial attack on the carrier starch, experiments have shown that the sedimentation was limited and the glue could be used.

Figure 4. Starch granules in glue without (left) and with 0.1% Exilva (right). Exilva is stabilizing the adhesive by creating strong networks with starch. The SEM analysis is performed by researchers in Professor Lars Berglunds group at KTH, Sweden.

Conclusion

So to conclude, Exilva brings robustness to the starch adhesives, which may prolong shelf life and give possibility for over-weekend storage. Moreover, Exilva brings robustness towards mechanical impacts, such as the pressure from pumps over long distances.

Next, what are the effects on productivity and the quality of the corrugated boards? Continuing this series, my next posts will be on glue ability and board properties with Exilva. And yes, you can look forward to some great improvements.

While waiting, have a chat with us to discuss potential effects on your formulation;

Written by:

Synnøve Holtan

Synnøve Holtan has worked with microfibrillated cellulose MFC since 2005 and has developed an in-depth understanding of the product characteristics, as well as production processes and application innovation. As a senior scientist at Borregaard she focuses on the analyses and performance of Exilva in industrial applications, such as coatings and adhesives. Synnøve has a PhD in biopolymer chemistry from the Norwegian University of Science and Technology.