Exilva Microfibrillated Cellulose & Polyurea: anti-settling & anti-sedimentation because of yield stress

Ole Martin Kristiansen | July 23, 2019

Modified polyurea and Exilva Microfibrillated cellulose (MFC) can both be used as rheology modifier in a variety of industries to prevent sedimentation and settling. In this article, I review the ability of the materials to give a yield stress in a waterbased system and, because of that, provide anti-settling & anti-sedimentation behavior. Tune-in on a comparison between these two rheology additives.

Polyurea’s are synthesized polymers that can form a reversible three-dimensional (3D) network consisting of hydrogen bonds. Urea groups have a highly favorable composition to form strong hydrogen bonds with one another and with other components that are able to form hydrogen bonds. At low shear, a system containing a polyurea rheology additive has a high viscosity (or even a yield stress). At high shear, the hydrogen bond network breaks down and the viscosity drops.

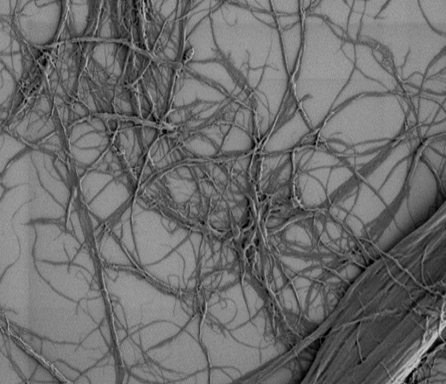

Microfibrillated cellulose is a waterbased suspension consisting of long and thin cellulose fibers, called fibrils. At low shear, the fibrils entangle with one another, thus forming a strong three-dimensional network.

Figure 1. A microscopy photo of the fibrils of microfibrillated cellulose.

Both Exilva microfibrillated cellulose and polyurea can give a yield stress in waterbased systems and both additives give a shear-thinning rheology.

--> Interested in the concept of yield stress and anti-settling? Read the details here.

Polyurea and Exilva microfibrillated cellulose: anti-sedimentation and anti-settling behavior in a TiO2 dispersion

The viscoelastic properties of paints and coatings can be improved by adding products like polyurea and Exilva microfibrillated cellulose. By transferring the yield stress properties of Exilva MFC or polyurea rheology additives to the paint, you obtain stability against sedimentation and settling. The composition of waterbased titanium dioxide (TiO2) pigment dispersions (model formulations), containing a polyurea rheology additive and Exilva microfibrillated cellulose respectively, is given in Table 1.

Table 1. Composition of the titanium dioxide pigment dispersions. The amounts are in grams.

| Ingredient | Function | Reference | Modified Polyurea | Exilva MFC |

| Water | Carrier | 110.4 | 103.7 | 80.4 |

| Disperbyk-190 | Dispersant | 63.0 | 63.0 | 63.0 |

| BYK-024 | Defoamer | 6.0 | 6.0 | 6.0 |

| Rheology additive | Prevent sedimentation | – | 6.7 | 30.0 |

| Kronos 2310 | White TiO2 pigment | 420.0 | 420.0 | 420.0 |

| Grotan BA 21 | Preservative | 0.6 | 0.6 | 0.6 |

| Total | 600.0 | 600.0 | 600.0 |

The polyurea product is a commercial state-of-the-art modified polyurea rheology additive that is used to prevent sedimentation and settling in waterbased systems. The polyurea additive is supplied as a solution of 45 % of active material in organic solvent dimethyl sulfoxide.

The MFC rheology additive, Exilva F 01-V, is supplied as a suspension of 10% of MFC in water.

Table 2. Yield stress values of the TiO2 pigment dispersions containing 0.5% active rheology additive.

| Product | Type of Additive | Yield Stress (Pa) |

| Reference | No Additive | 0.43 |

| Exilva F 01-V | Microfibrillated Cellulose | 2.90 |

| Commercial modified polyurea | Dissolved Urea Polymer | 0.66 |

Table 2 shows the yield stress values of the TiO2 pigment dispersions containing Exilva F 01-V and the modified polyurea rheology additive. Exilva gives a higher yield stress compared to the polyurea product at the same active dosage. The big difference in yield stress implies that less Exilva can be used, compared to modified urea, to obtain the same degree of stability against sedimentation and settling.

Both technologies are based on a reversible three-dimensional (3D) network that is built-up and broken down, depending on the amount of shear applied. The high efficiency of the MFC product results from the entanglements of the cellulose fibrils, giving a strong physical network, Figure 1. A higher yield stress gives better anti-sedimentation and anti-settling properties.

Table 3. Some similarities and differences when comparing polyurea rheology additives

and microfibrillated cellulose.

| Modified Polyurea | Exilva Microfibrillated cellulose |

| SIMILARITIES | |

| Forms strong and reversible 3D network | |

| Gives strong shear-thinning behavior | |

| Provides yield stress | |

| Resistant against microorganisms | |

| DIFFERENCES | |

| Dissolved polymer | Insoluble cellulose fibrils |

| Based on hydrogen bonding | based on entanglements |

| Supplied as solution in organic solvent | Supplied as suspension in water |

| Not bio-based | 100% bio-based |

How can I add Exilva microfibrillated cellulose to test yield stress and anti-sedimentation/anti-settling?

Exilva microfibrillated cellulose is used in a wide range of applications. For paint producers, the optimal moment to add MFC is in the grinding step. When ensuring dispersion, by utilizing the strong shear forces in the grinding step, you will succeed in incorporating the yield stress properties of Exilva into your paint. For other application areas, in which polyurea rheology additives are used today, the important thing to remember is that Exilva microfibrillated cellulose should be dispersed by applying substantial shear forces.

Read up on proper dispersion of Exilva microfibrillated cellulose and request your free sample of Exilva today: