How can I control the rheology of my concrete better?

Tania Risson, Guest Blogger | October 30, 2018

Concrete products are a complex mixture of chemicals, fines, and heavy particles. It's always challenging to control the stability, flow and strength of it. Many admixtures have been created to overcome these challenges, often containing synthetically derived performance additives. I will here try to give you some input of one of the new technologies and how it affects various parameters in the concrete.

Stabilizers in Concrete

To control the rheology of concrete is key. Bleeding and particle segregation is a significant problem with concrete. The concrete has to be stable and robust against segregation of aggregate and bleeding. This can be obtained in at least two ways: By adding fine particles and/or filler, and/or by adding stabilizers. Viscosity modifying agents (VMA) like cellulose ethers, natural gums (xanthan, wellan) and starch are often used in concrete as stabilizers. They mainly act by increasing the paste viscosity to reduce risks of bleeding and segregation. The mechanism of action is different for the cellulose fibrils/nanocellulose.

Increasing yield stress with minimal effect on plastic viscosity

Cellulose fibrils/nanocellulose is an efficient tool to enhance the yield stress of concrete mixtures. Yield stress is the minimum stress for flow to occur and is important for many products and applications around us. Roussel (2005) describes this as the shear stress meeting the yield stress, thus initiating the ability of the cementitious material to start flowing.

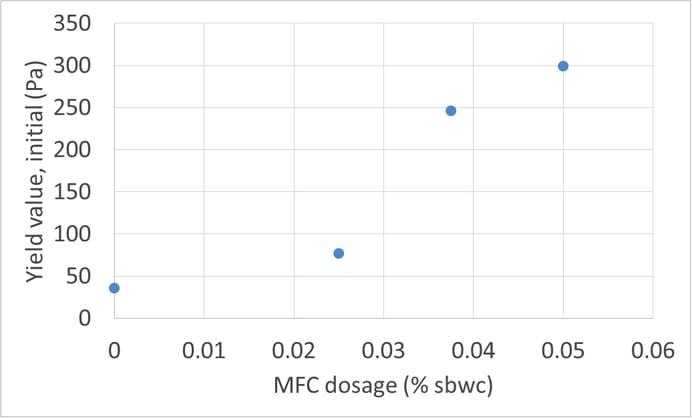

Through our own tests at Borregaard, we have studied the effect the fibrils has on slump value and yield value (in self-consolidating concrete, SCC). We found that with quite a low dosage of cellulose fibrils/nanocellulose the slump decreased significantly. The result and conclusion from these tests were that by changing the dosage of the fibrils, in relation to the weight of the cement, one can fairly effectively adjust the yield value of the concrete.

Figure: Yield value as a function of cellulose fibrils (Exilva, Borregaard) dosage by weight of cement (sbwc = solid by weight concrete).

This is beneficial to many applications in the concrete field. For instance, increased yield stress

- results in a lower pressure exerted on the formwork by the concrete when placed (highly fluid mixes / SCC)

- is beneficial for underwater concreting (to prevent wash out)

- is an advantage for sprayed concrete/mortar/renders (to reduce rebound, improve “adhesion” to substrate, improve stability…)

- helps concrete placing by extrusion (smooth surface finish and good concrete cohesion)

Stabilizing effect

Cellulose fibrils/nanocellulose also provides a very interesting non-soluble network, that may help to avoid settling in concrete. Its ability to provide a physical support to the concrete matrix may, in theory, increase the opportunity to enhance the stability of the concrete at rest.

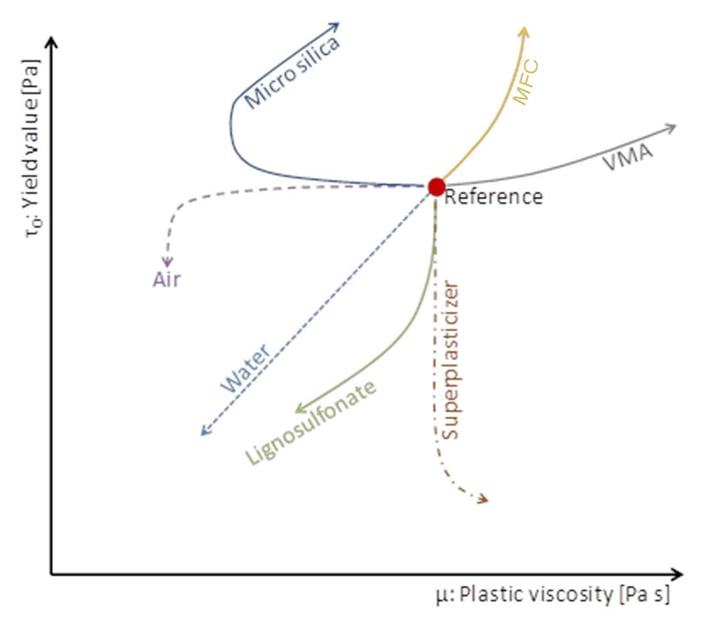

The following rheograph shows a typical effect of different materials on the rheology of concrete [1, 2]. It visualizes how different the various families of stabilizing agents are in terms of mode of action (VMA refers to viscosity modifying agent).

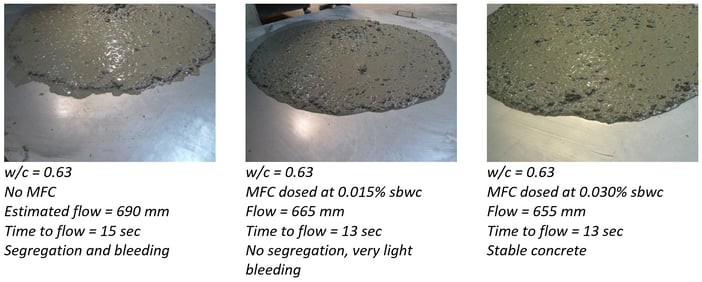

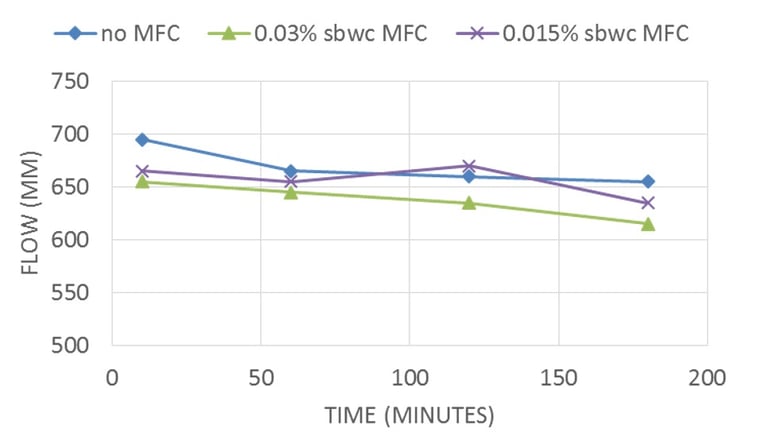

The following figure shows that a very small addition of fibrils allows to stabilize a concrete mix. An addition of 0.015% sbwc of cellulose fibrils/nanocellulose indeed prevents segregation and bleeding without impacting the “time to flow”. “Time to flow” can, to some extent, be related to viscosity.

It has no detrimental effect on workability retention, contrary to silica fumes for instance, which are also frequently used to stabilize highly fluid mixes.

→ Read also: What is Microfibrillated Cellulose (MFC)?

REFERENCES

1. O. Wallevik, Course in Rheology of particle suspension, University of Reykjavik, Iceland, November 2011.

2. O. Wallevik, J. E. Wallevik, Rheology as a tool in concrete science: The use of rheographs and workability boxes, Cement and Concrete Research 41 (2011), p. 1279-1288.

---

This post was originally first published in August 2016, but we've updated it with new information and knowledge to make it up to date.

Written by:

Tania Risson, Guest Blogger