Prolonged open time for exterior wood stains. Why coffee breaks are important!

Synnøve Holtan | July 4, 2017

The open time, wet edge or lapping of a coating is a measure of how much time an air dry coating takes to reach a stage where it can no longer be applied by brush or roller to the same "wet" coating without leaving an indication on drying that the "wet" and newly applied coating did not quite flow together. Therefore, the advantage of having good open time in a stain would result in better general appearance of the stain.

The stain would keep a wet edge longer and not show lap marks, brush or roller tracking and uneven appearance. The ideal semitransparent stain would penetrate the surface (not form a visible film on the surface) and keep a good wet edge. I will here try to show you the effect of microfibrillated cellulose (MFC) on open time for an exterior acrylic based red oxide stain.

Measuring open time of wood stains formulated with MFC or HEUR

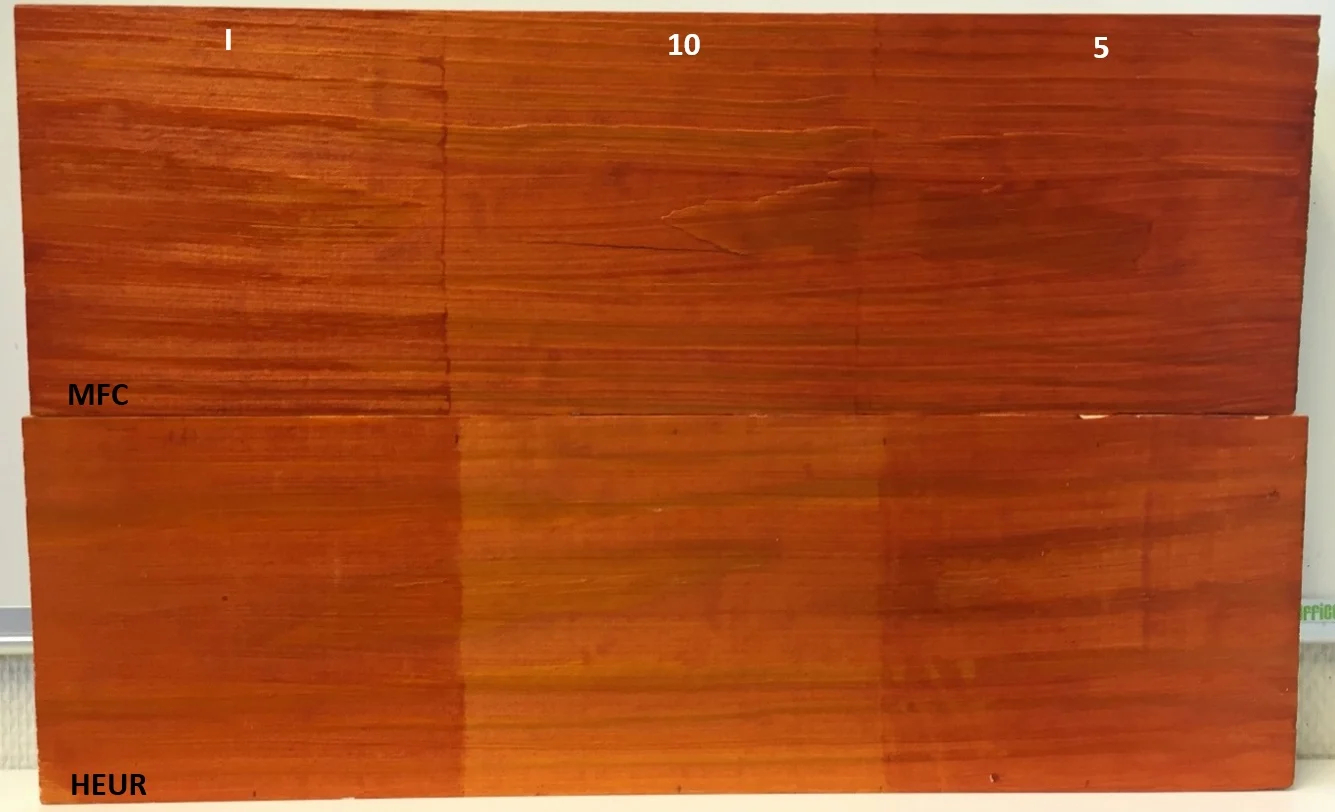

Two acrylic based red oxide stain formulations, one with 0.2% of MFC 1 (Exilva F 01V, Borregaard), and one with 0.2% MFC 2 (Exilva P 01V, Borregaard) on total formula weight, were compared to the same formulation based on 0.2% hydrophobically modified ethylene oxide urethane (HEUR) rheology modifier. To test open time, the stain was applied to the I (Initial) portion of a cedar panel, see Figure 1. After 5 minutes, stain was applied to the opposite side of the panel, portion 5 (5 minutes). After an additional 5 minutes (10 minutes total), stain was applied to the entire panel. The amount of stain applied was controlled. The panel was then rated for visual color differences and wet edge lines at the 5 minute and 10 minute sections. The area marked I has two coats applied 10 minutes apart. The area marked 5 minutes has two coats 5 minutes apart. The area marked 10 has 1 coat.

Figure 1. Open time evaluation on cedar wood panels. Upper panel: Acrylic red oxide stain formulated with MFC 2 (Exilva P 01V, Borregaard). Lower panel: the same stain formulated with HEUR.

Figure 1. Open time evaluation on cedar wood panels. Upper panel: Acrylic red oxide stain formulated with MFC 2 (Exilva P 01V, Borregaard). Lower panel: the same stain formulated with HEUR.

From the panels in Figure 1, the Exilva P 01V MFC stain applied on the upper panel and the HEUR reference stain applied on the bottom panel, it is apparent that MFC is improving the general appearance of the stained wood, reducing the color difference, brush marks and visible wet edge lines. Furthermore, by formulating with MFC there is no difference in the appearance between one or two coated layers, even with 10 minutes between application of the stain (Figure 1, upper panel, I and 10 portions).

In the Table 1 the results for the open time test is shown. The wet edge was rated 0-10, where 10 is the best with no visible lines, and 0 is the worst designating poor wet edge (see Table 1). The both panels with stain formulated with MFC (MFC 1 and MFC 2 , respectively) had the best appearance and was rated 7 for MFC 1 and 8 for MFC 2, after 5 minutes different application time, whereas the panel with the HEUR stain was rated 6. After 10 minutes different application time, the MFC stains were rated 5 and 6, respectively, whereas the HEUR stain was rated 3.

| Open time, Wet edge 10 = No Visible Lines 0 = Poor Wet Edge |

Stain with HEUR | Stain with MFC 1 (Exilva F 01V) |

Stain with MFC 2 (Exilva P 01V) |

| 5 minutes | 6 | 7 | 8 |

| 10 minutes | 3 | 5 | 6 |

Table 1. Wet edge measurement of wood stains formulated with MFC or HEUR

How MFC increases the open time of stains

As this study shows, the use of MFC in wood stains gave a better wet edge and open time, compared to the HEUR reference upon application on cedar panels. The large surface area of MFC with functional OH-groups provides MFC with an ultrahigh water holding capacity. Most probably this high water retention property, secures a prolonged open time for wood stains. Moreover the rheological effect of MFC is controlling the viscosity and penetration of stain into the wood substrate. Two qualities of MFC with different fibril surface area and network properties were tested in this study, and they both gave better open times for the stain than the reference with HEUR.

So while the addition of MFC extends the time window for applying a new layer and enables correcting defects in the coating layer without brush marks; take a break from painting and drink another cup of coffee.

Written by:

Synnøve Holtan

Synnøve Holtan has worked with microfibrillated cellulose MFC since 2005 and has developed an in-depth understanding of the product characteristics, as well as production processes and application innovation. As a senior scientist at Borregaard she focuses on the analyses and performance of Exilva in industrial applications, such as coatings and adhesives. Synnøve has a PhD in biopolymer chemistry from the Norwegian University of Science and Technology.