Stabilisation of biological formulations in agriculture

Rebecca Blell | November 16, 2021

The last few years have seen a very fast increase in the use of biologicals and biocontrol agents in crop protection and agricultural products as part of the shift towards more sustainable and environmentally friendly agriculture.

Biologicals are products derived from nature. They can be living organisms or naturally occurring materials with pest control ability. Their use is one of the ways the industry is improving Residue* and Resistance* management, two of the biggest concerns with chemical crop protection actives.

Performance and Stability Requirements with Biobased Additives

There is a strong need to find biobased inerts and additives with good tolerance to microorganisms, good compatibility with most formulation ingredients and that will maintain good product stability and performance. Since the product formats containing biologicals are mostly like the ones with synthetic chemicals, the requirements for formulation stability and homogeneity during storage, handling and application remain very important. One big difference is that in this case, it is of high importance that the living organisms remain viable and at a constant level to maintain product performance.

The strong shift towards biobased and microplastic free additives does not make the formulator’s life any easier. The standard additives used today are not always an option as they are either non-biodegradable, non-biobased or are biobased but not compatible with living organisms.

As many know, some biobased additives used in crop protection formulations have very low tolerance to microorganisms. They typically need to be preserved when dissolved or dispersed in water to limit their degradation and loss of performance. Gums used for rheology control and stabilization in suspensions are examples of biobased additives that typically need to be preserved. The challenge is that using a biocide is in direct contradiction with the purpose of keeping the living organisms viable.

If this is a problem you are trying to solve, Borregaard’s Microfibrillated Cellulose Exilva is an excellent structuring agent you should consider. Exilva has high stability with microorganisms and is delivered as a biocide free suspension or paste with water.

suspending ability compared to Xanthan Gum

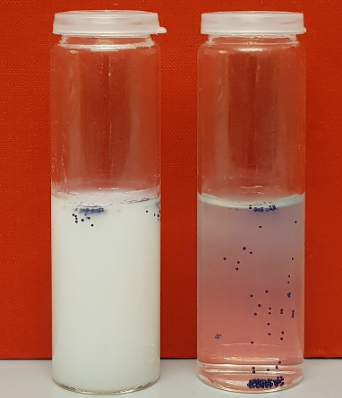

We have demonstrated that Exilva maintains its suspending ability over time, even when non preserved, while xanthan gum loses performance in less than a month without a biocide.

After one month (Exilva on the left, Xanthan Gum on the right).

Exilva maintains its suspending ability after atleast 1 month without biocide.

--> Check out our full blog post about microbial stability here: Stability of Cellulose fibrils — microbial degradation

The robustness of Exilva with microorganisms is explained by:

- Its non-soluble but biodegradable network of cellulose fibrils

- It is made from high purity cellulose pulp

In addition to acting as a suspending aid, it is highly compatible with many formulation conditions and could be used in a wide range of liquid products and applications (crop protection products, plant nutrition and liquid fertilizer, seed coatings and treatments). Other advantages that give the formulator flexibility during formulating with Exilva include high salt, temperature and pH tolerance, and strong compatibility with water and polar solvents.

*One problem with synthetic chemicals used as crop protection actives is their tendency to linger long in the fields and not degrade fast enough. In addition to increased residue, these chemicals lead to pesticide resistance, also defined as the ability of a pest to develop a tolerance to a pesticide. Residue and Resistance management are programs used to prevent this development.

Interested in learning more about this topic? Contact one of our experts through the button below, or leave a comment!

Written by:

Rebecca Blell

Rebecca first started working with microfibrillated cellulose in 2009, during her studies, as part of the SustainComp project. She joined Borregaard in 2014 as a research scientist and focused on the Exilva product and its performance in cleaning products, cosmetics and agricultural applications. She is now working as the Technical Application Manager for these applications in parallel to being Technical Sales Manager for Exilva products in France and UK. Rebecca has a PhD in physical chemistry from the University of Strasbourg, France and experience from international companies.