Improved barrier coating performance with Exilva

Otto Soidinsalo | July 1, 2022

Recent awareness in sustainability as well as changes in the legislation regarding single-use products, has put significant pressure on the whole packaging industry. Although fiber-based packaging is regarded as the solution for replacing plastic, the current solutions have big challenges regarding, for example, the recyclability.

Traditionally, barrier properties against grease, oil, oxygen and liquids are achieved with extrusion polymers like polyethylene (PE) and EVOH. Due to the challenges in recyclability of these products as well as the regulatory issues related to the extrusion coated fiber packaging, there is a strong need to find new, sustainable barrier solutions. Water based dispersion coatings are currently seen as the top candidates for replacing PE coatings on fiber substrates, leading to 100% recyclability and in some cases in compostable packaging. However, the quality requirements for the fiber base materials are significantly higher than in the case of extruded barriers.

Improved process robustness and runnability

Dispersion barriers are applied on various fiber substrates, ranging from wrapping papers to board and fiber molded products. Due to the differences in the packaging materials surface properties, such as porosity and smoothness, it´s typically difficult to obtain good barrier properties with one dispersion coating formulation.

In order to have smooth and pinhole free barrier coating, the focus is often put on improving the properties of base paper, board or fiber molded products. This approach naturally requires adjusting the process from furnish to forming and drying, meaning multiple and costly trials.

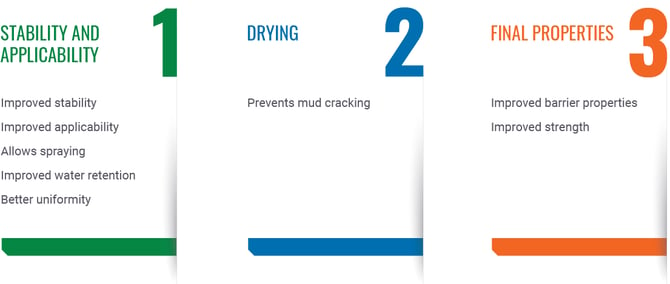

Another, faster and more cost efficient option is to approach the challenge by optimizing the dispersion barrier coating formulation. With Exilva, one can formulate a stable and robust water-based dispersion barrier coating, which can be applied on all substrates without the need of substrate or process optimization. Instead of adjusting the substrates, addition of Exilva ensures improvement from formulation to the final properties of the packaging (Figure 1.)

Figure 1. Impact of Exilva on dispersion barrier coatings.

Significant improvement in barrier coating performance

One of the benefits of Exilva on the performance of the barrier coating is its impact on the water retention of the coating. Water retention plays a significant role in the coating process. If the water retention is too low, the water will penetrate into the base, leading to poor film formation and poor barrier properties. On the other hand, too high water retention can lead to challenges in adhesion as well as cracking during the oven drying step. With Exilva, the optimal level of water retention can be achieved, leading to improved barrier properties (Figure 2).

Figure 2. Water retention of styrene acrylic dispersion, reference (1), samples 2-4 with increasing amount of

Exilva F 01-V on paper between 1-5 minutes.

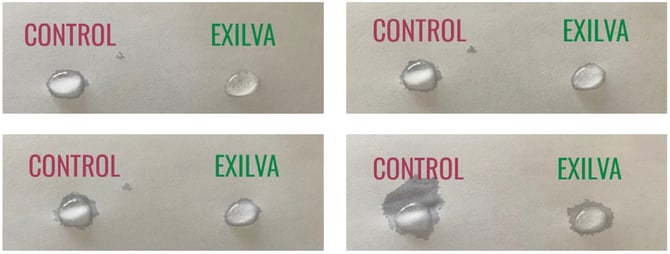

The unique shear thinning of Exilva, combined with good levelling properties leads to better uniformity and a pinhole-free barrier coating (Figure 3).

Figure 3. Water permeability test results after 1 min, 2min, 3 min and 5 min of a biodegradable barrier coating on a kraft paper.

Summary

The unique rheological properties of Exilva allows easy pumping and spraying as well as good runnability of barrier coatings. The unique low shear viscosity ensures good water retention, meaning that less focus is needed for the control of the water absorption of the base. With the aid of Exilva you can use one barrier coating formulation for multiple substrates, ranging from fiber molded to wrapping papers and ensure good barrier properties.

Supportive technical bulletins available on request.

Want to try Exilva in your formulation? Get in touch with us here, or:

Written by:

Otto Soidinsalo

Dr. Otto Soidinsalo holds a Ph.D. in organic chemistry from the University of Helsinki. Currently he works as a Technical Application Manager at Borregaard. Before joining Borregaard, Otto was working in various positions in pharma and cellulose derivatives related industries for 8 years, ranging from R&D to product and application development and technical services. Currently Otto is focusing on CASE as well as on paper & packaging applications, especially on barrier coatings. Otto possesses a deep understanding of the natural polymers and their derivatives and their impact on rheology as well as mechanical properties of various applications.