Water based waterproofing elastomeric coatings, especially roof coatings, have become a hot topic lately. One reason for this is that they reduce the heat absorption of the buildings when compared to the traditional asphalt roofs. In addition to heat prevention and energy savings, waterproofing coatings protect the underlying surface from water, UV radiation, chemicals, and deterioration.

Posts about Coatings

Recent awareness in sustainability as well as changes in the legislation regarding single-use products, has put significant pressure on the whole packaging industry. Although fiber-based packaging is regarded as the solution for replacing plastic, the current solutions have big challenges regarding, for example, the recyclability.

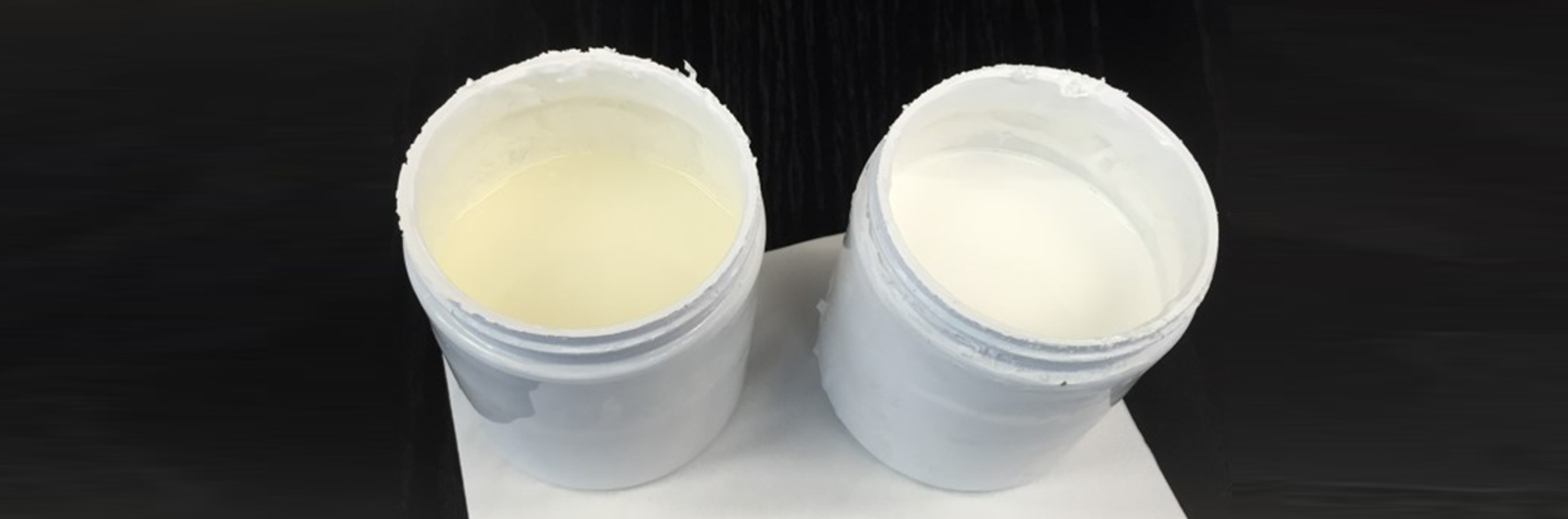

With an increasing trend to more environmentally friendly and low VOC paints, waterborne coatings are becoming more favoured over solvent-based coating, due to their lower solvent concentration.

Undesirable phenomena such as sedimentation and settling can often occur during the storage of paints. Therefore, a re-dispersion step is necessary which can mean additional cost. These challenges can be even more pronounced in high solid content formulations and so it is crucial to secure stability of those systems. To avoid these effects, rheology modifiers need to be added to paint formulations. So, I prepared some information for you and conducted a couple of tests with the rheology additive nanocellulose to show you how focus on yield stress will reduce sedimentation and settling.

Paint manufacturers have been formulating paints containing microspheres in many years. Formulators can use microspheres to increase the solid content of a coating while maintaining the proper application and flow characteristics. Higher solids can reduce volatile organic compounds (VOCs), shrinkage and drying time. But there can be problems with settling and sedimentation, as well as floating of the microspheres. In addition, cost of certain types of microspheres can be high.

Sedimentation of solid particles in liquid materials, like paints and inks, is caused by gravitational force pulling particles of high density down. In the worst case, sedimentation can result in settling, the formation of a hard layer of solid material on the bottom of the can. How to avoid this?

Coating performance is often very complex, and can depend on the coating system itself, substrate to be coated, conditions during coating etc. Increasing the performance is often a lengthy process with multiple tests on wet paint performance and dried coating performance. Key aspects of wet paints can be control of rheology, and for solid coatings the ability to improve endurance. Are there technologies available for aiding on the key aspects? For sure. Are there new sustainable additives which can improve the new water borne technologies? Let me show you an example of exactly that in this blog post.

Subscribe to our newsletter

Stay up to date with the latest from The Exilva Blog and receive the latest news straight to your inbox.