MFC can help thicken your advanced cleaning products

Otto Soidinsalo | April 28, 2020

There is a strong need to disinfect and sanitize frequently touched surfaces. Exilva Microfibrillated cellulose (MFC) is a biobased structuring agent that can thicken household disinfectant and cleaning products at low to high pH, as well as with oxidizing compounds.

The CDC have listed the following as frequently touched surfaces: Tables, doorknobs, light switches, countertops, handles, desks, phones, keyboards, toilets, faucets, sinks, etc. (1)

If you look at any recommended list of disinfectants, you will notice that many of these household and industrial cleaners are strongly alkaline, highly acidic or contain oxidizing agents. Secondly, the required contact time of common disinfectants varies from 1 up to 10 min.(2) This naturally creates challenges for the formulators to find a suitable thickener which would allow easy spreadability and ensure required dwell time. In many cases, viscous, gel or foam formulations are also preferred, as they are considered safer to use, mainly by preventing any unwanted splashing.

Today we will look at how MFC allows you to manufacture stable gel formulations which are easy to apply and ensure sufficient contact time at low to high pH as well as with oxidizing compounds, such as hydrogen peroxide.

Today's challenges

The biggest challenge regarding the thickening of highly acidic or alkaline products, as well as oxidizing compounds such as bleach, is to find a stable rheology modifier. Most of the common rheology modifiers have a narrow pH working range and are often vulnerable to oxidizing agents. The chemical instability of the compounds leads to a short shelf life of the end product. In addition to the chemical stability, the rheology modifier should also provide a drip resistant profile for the formulation.

Current solutions

Many toilet bowl and bathroom cleaners, that are tailored to remove scale and rust, have a pH below 3 and are often based on hydrochloric acid. On the other hand, several cleaning products are based on sodium hypochlorite, typically stabilized with sodium hydroxide to pH 10-13. As can be seen from the list below, the amount of suitable thickeners is low (Table 1.), especially when you are targeting high pH formulations with oxidizing agents.

Table 1. Stability ranges of common thickeners used in cleaning products.

| Compound | pH range | Oxidizing agents |

| Carbomers | 3–13 | Some |

| Xanthan | 2–12 | Not stable |

| Cellulose ethers | 3–11 | Not stable |

| Magnesium aluminium silicate | 2–13 | Stable |

📖 Want to learn more on the storage stability of Exilva under a wide pH range? We have previously written about the subject.

Thickening with MFC

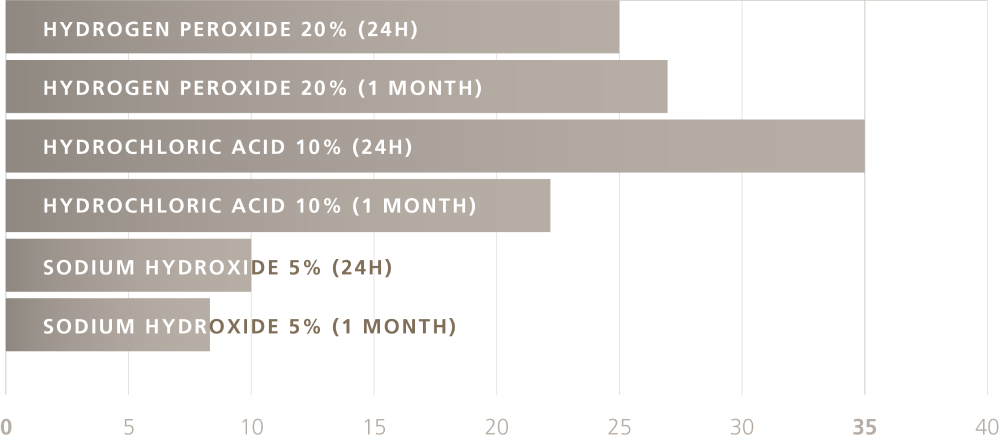

Due to its insoluble nature, MFC shows considerably higher stability against chemical reactions than water soluble polymers. Figure 1 shows the complex viscosities of 1% Exilva in 5% sodium hydroxide (NaOH), 10% hydrochloric acid (HCl) and in hydrogen peroxide (H2O2), after 24 hours as well as after 1 month storage. As can be seen from the figure, MFC effectively thickens these media as well as shows good storage stability.

Figure 1. Complex viscosities (Pas) of 1 wt% MFC (Borregaard’s Exilva MFC) suspensions after 24 hour and 1 month storage at room temperature.

The high stability of MFC allows it to be used to thicken various home care and industrial cleaning products such as, toilet bowl cleaners, bathroom cleaner, degreasers, metal cleaners, rust removers and car cleaners. The high chemical stability is also important in various other application fields such as coatings and adhesives.

In addition to the chemical stability, MFC provides exceptional rheological properties and outstanding compatibility with various compounds such as surfactants. Due to the high viscosity at rest as well as high shear thinning, one is able to design formulations that are easy to spray as well as non-dripping (Figure 2).

.jpg?width=861&name=Anti-settling_Exilva_spray%20(1).jpg) Figure 2. Anti-sag and spray properties of sprayed MFC formulation. The emulsion on the left hand side is a reference without MFC. The right hand side formulation contains 0.3% MFC (Borregaard’s Exilva MFC) which effectively prevents dripping on non-horizontal surfaces.

Figure 2. Anti-sag and spray properties of sprayed MFC formulation. The emulsion on the left hand side is a reference without MFC. The right hand side formulation contains 0.3% MFC (Borregaard’s Exilva MFC) which effectively prevents dripping on non-horizontal surfaces.

Summary

MFC offers a solution for those who are looking to simplify their formulations or have fewer additives on their shelf. In addition to the high performance and stability, MFC is a renewable choice for your challenging formulations, taking you one step closer to sustainable products.

For more information on Cleaning and disinfecting your facility, please go to the CDC website:

- Cleaning and disinfecting your facility: https://www.cdc.gov/coronavirus/2019-ncov/community/disinfecting-building-facility.html

- List N: Disinfectants for Use Against SARS-CoV-2: https://www.epa.gov/pesticide-registration/list-n-disinfectants-use-against-sars-cov-2

Written by:

Otto Soidinsalo

Dr. Otto Soidinsalo holds a Ph.D. in organic chemistry from the University of Helsinki. Currently he works as a Technical Application Manager at Borregaard. Before joining Borregaard, Otto was working in various positions in pharma and cellulose derivatives related industries for 8 years, ranging from R&D to product and application development and technical services. Currently Otto is focusing on CASE as well as on paper & packaging applications, especially on barrier coatings. Otto possesses a deep understanding of the natural polymers and their derivatives and their impact on rheology as well as mechanical properties of various applications.