Clay (including montmorillonite and bentonite) additives and Exilva microfibrillated cellulose (MFC) have a lot in common since they both can be used as rheology modifier in different industries. However, there are also clear differences. In this article, I will review the ability of the materials to provide yield stress and subsequent anti-settling & anti-sedimentation benefits. Tune-in on a comparison between two of the most potent anti-settling & anti-sedimentation additives available.

Exilva microfibrillated cellulose and fumed silica are both used for controlling the rheology of liquid systems, such as anti-settling and anti-sedimentation. But when we are comparing the two technologies, we also see differences. In this article, we will show you how the microfibrillated cellulose and fumed silica builds yield stress, and how they consequently can give good anti-settling and anti-sedimentation benefits.

Surfactants are present in most consumer products. The most familiar examples are shampoos, hand wash products and cleaning products in general. Switching to sulfate free surfactants improves the environmental profile, but can be a challenge. Let me show you a way to this.

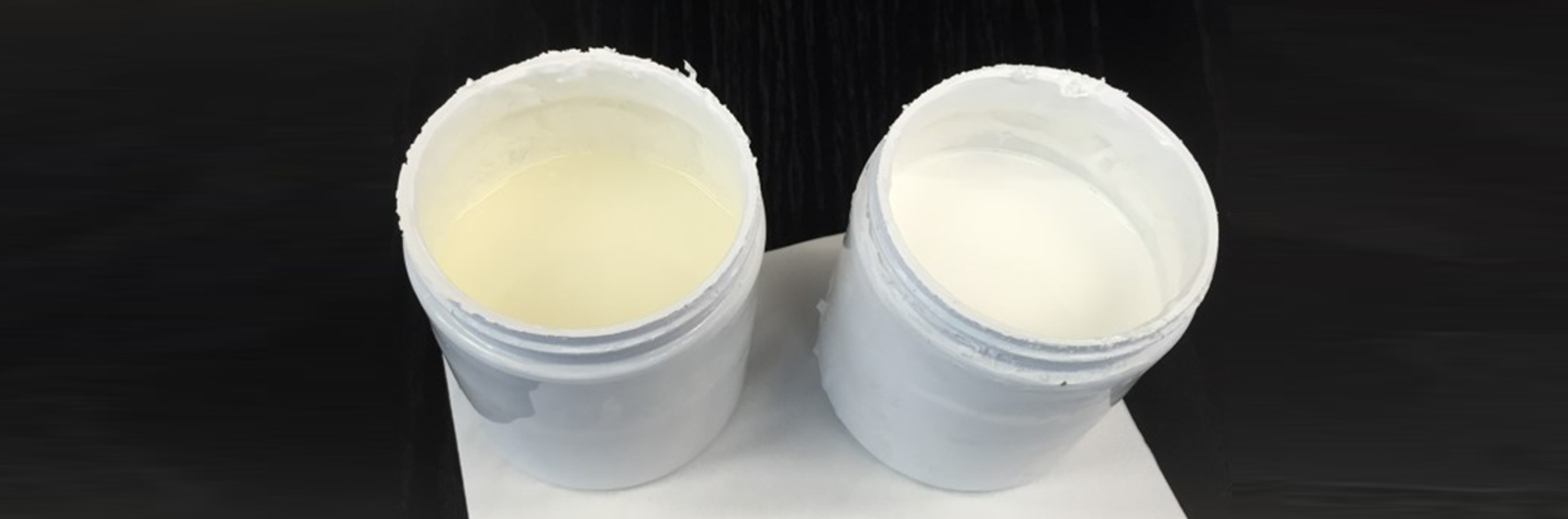

I will demonstrate that one can use cellulose fibrils to thicken and stabilize formulations with foam forming surfactants. The most important point to remember when preparing such formulations is to avoid foam formation during the incorporation step of surfactants with the cellulose fibrils.

What is heat of hydration, and how does it affect the settling and curing phase of the concrete? Learn more about different types of concrete cracking, why they occur - and preventative measures and repair methods for fixing it in this Topic Tuesday. Hint: there are bio-based alternatives available!

Gypsum boards (plasterboard/drywall) are a very commonly used product in the construction industry. Currently, the production of the boards is a labor-intensive, CO2 producing and energy consuming process with the need for many synthesized additives to retain the flow, strength and setting profiles. What if you could change that?

Sedimentation of solid particles in liquid materials, like paints and inks, is caused by gravitational force pulling particles of high density down. In the worst case, sedimentation can result in settling, the formation of a hard layer of solid material on the bottom of the can. How to avoid this?

The scientific method Life Cycle Assessment (LCA) is a tool originally developed to scrutinize the environmental performance of products, product systems or services. In recent years, the LCA framework has been expanded to include all aspects of sustainability. This blog post will present what LCA is, how it has developed historically and why you should care about it.

Often the word sustainability is used to designate that something is good, without any specification of good for what or good for whom. It’s time to put some hold to the phrase ‘sustainable’. Learn more on what it means and what you need to keep in mind when talking about sustainable products or solutions.

When most people were talking about the brutal polar vortex that hit Chicago earlier this year, I am sure many were looking for ways to best protect the products they are producing, transporting, storing and using from being destroyed by freezing. In this blog post, I will briefly mention a few tips on how to make products freeze-thaw stable such that they can be used in winter harsh areas.

Subscribe to our newsletter

Stay up to date with the latest from The Exilva Blog and receive the latest news straight to your inbox.