Trouble with cracking during drying of your coating, adhesive, putty or other products?

Ole Martin Kristiansen | May 22, 2018

One of my favourite characteristics of the cellulose fibrils is its behaviour when drying or involved in the drying process of a product system. I have learned through some of our conducted tests that cellulose fibrils can act in an interesting and often beneficial way towards obtaining desired end product characteristics. Most of the examples on how the fibrils influence the drying are related to coatings. I however believe that similar behavior is possible to observe in application areas where a tight control of dry-out properties is desired. Evaporation of solvents is often the main technique for drying in many applications. I will therefore focus my blog post this time on this specific drying technique. Let me share some very interesting insights into why cellulose fibrils are improving the products upon drying.

Controlling the evaporation of solvents: how do we think cellulose fibrils are contributing to drying

In water based systems, one of the fastest growing technologies within adhesives and coatings applications, the main method used for drying is so-called convection drying. In convection drying, the water evaporates, influenced by several factors such as the humidity (relative), the air speed, and of course time. All these aspects play different roles depending on the equipment you use. Huge difference in behavior can for instance be observed if induction drying is compared to convection drying. The film formation of the coating, putty etc. behaves differently, and might even depend on the type of surfactants used.

Coatings, adhesives and putties are normally built up by polymers which at a certain time during the drying process go together and create a continuous film. It has not been typical to include non-soluble rheology additives in this context before, and this is where the cellulose fibrils are different. We have previously written about the rheology effect of the three-dimensional network of cellulose fibrils, but let me try to explain how this is also affecting the parameter of drying using the coatings field as an example.

When the cellulose fibrils are incorporated into for example an adhesive formulation in an optimal manner (by using high shear mixing), they form a homogeneously spread three-dimensional network within the product’s matrix allowing for the strong water affinity of all the available OH groups on the fibrils’ surface to give strength and improved stability to this network, as well as to the formulation as a whole. This improves the stability of the formulation on the shelf and creates performance functionalities during the application process.

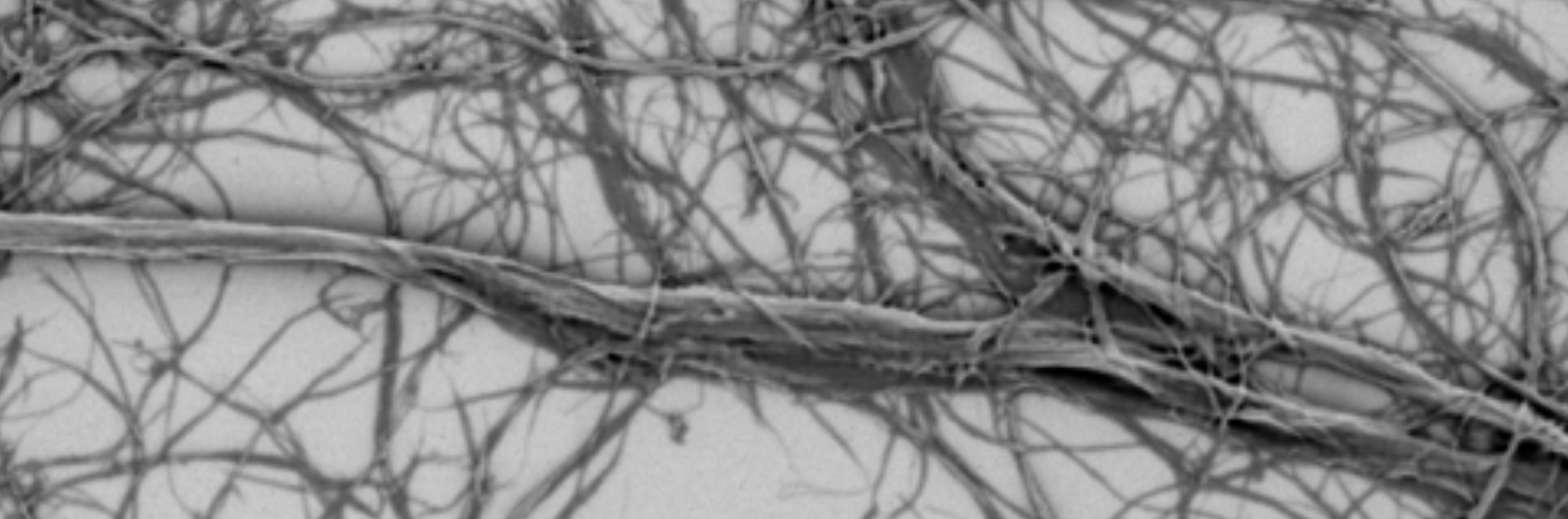

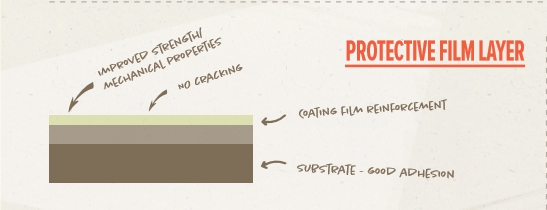

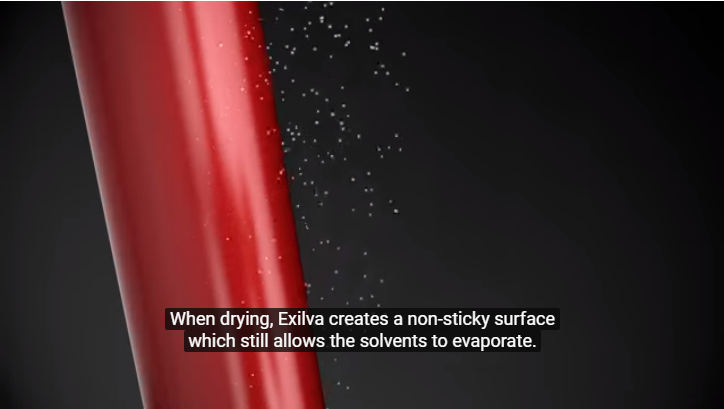

These same fibrils impact the drying process. Due to the presence of the fibrils, the film stays open during the entire solvent evaporation process, decreasing issues like blistering while at the same time removing stress in the film during drying (see sketch and picture below). At sufficient use dosage, the fibrils improve the strength of the film.

Picture 1: Courtesy of Borregaard (Exilva cellulose fibrils).

What’s the practical benefits of this?

- You may increase your coating thickness without sacrificing the coating’s film strength and drying behaviour

- You may improve coatings, adhesives or putties (and possibly other systems as well) where cracking is an issue

- For the ones out there living in cold climates for a large part of the year, this effect can give a prolonged painting season (you can paint down to 2 degrees Celsius without seeing the cracking problem1.

1 Tests results from Borregaard on the Exilva microfibrillated products,

Picture 2: Screenshot from Exilva video, courtesy of Borregaard.

Are you selling or distributing coatings, adhesives, putties or other types of products where drying is an issue? This rheology technology platform of cellulose fibrils giving additional effects could for certain be interesting. This is especially true if you are looking for thicker coatings with improved drying functionalities, or even looking to extend the painting season of your products. If you come up with a good solution for this, please be in touch and let me try your new formulation!