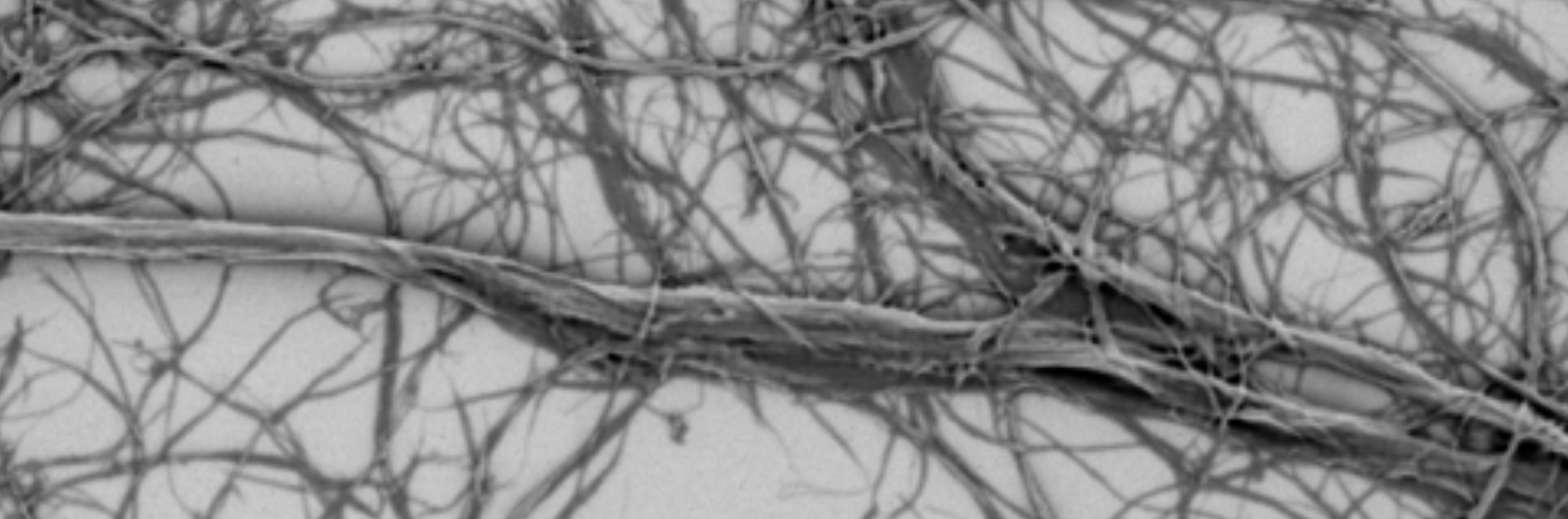

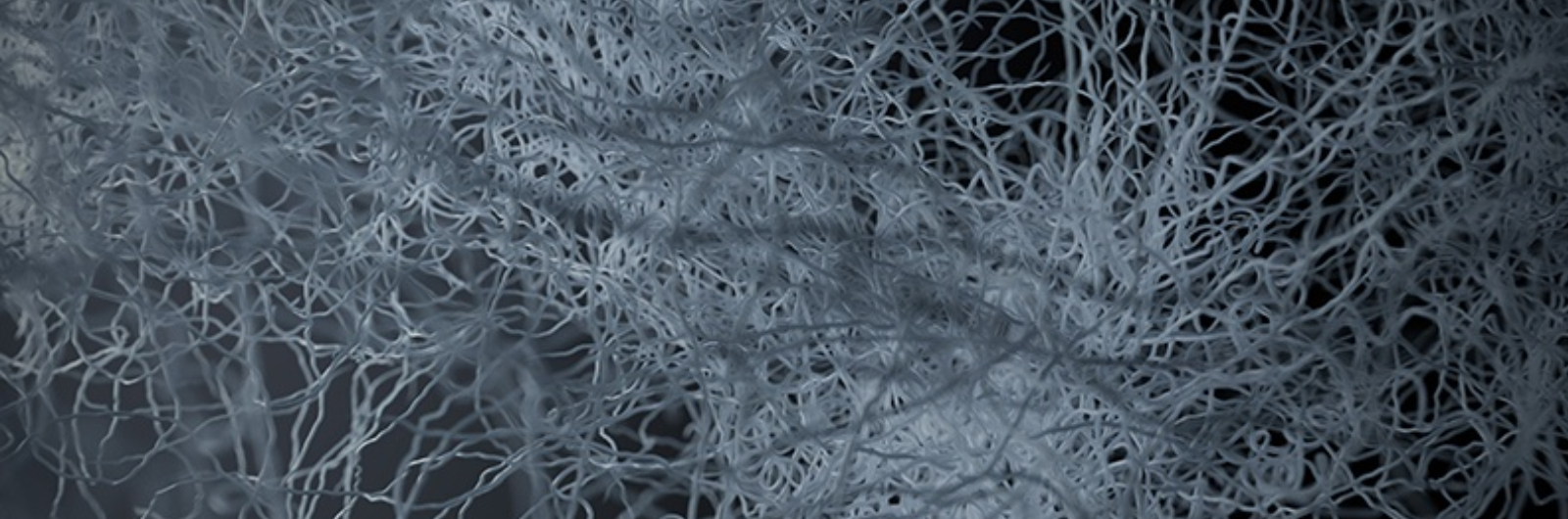

Bio-based is on everyone's lips these days, and there are a high number of initiatives going on in innovating new product systems with a bio-based background. In this post I will give you a sneak peak into the improvement of an organic solvent system, using a biobased additive as an example. Cellulose fibrils is a green and environmentally friendly material that consists of a complex three dimensional network of cellulose microfibrils.

Exilva® is Borregaard's innovative additive within the field of Cellulose fibrils / Microfibrillated cellulose (MFC). It is a natural and sustainable bio-based problem solver, that improves rheology and stability in product formulations. Through this blog you will learn more about the potential impact you can get from this wonderful product.

Are you looking for a new additive for controlling rheology? In this article if will give you an explanation of the typical and well known rheology additive, and the Exilva Microfibrillated cellulose.

Ever heard about bouligand structures or tunicates? And how are these topics relating to nanocellulose? This week’s research review is giving you a summary of some really exciting news relating to strength performance from nanocellulose (nanocrystalline cellulose). In addition, we are bringing you news on nanocellulose as an art-preservation aid. Spend 4 minutes and read through some really interesting updates.

One of my favourite characteristics of the cellulose fibrils is its behaviour when drying or involved in the drying process of a product system. I have learned through some of our conducted tests that cellulose fibrils can act in an interesting and often beneficial way towards obtaining desired end product characteristics. Most of the examples on how the fibrils influence the drying are related to coatings. I however believe that similar behavior is possible to observe in application areas where a tight control of dry-out properties is desired. Evaporation of solvents is often the main technique for drying in many applications. I will therefore focus my blog post this time on this specific drying technique. Let me share some very interesting insights into why cellulose fibrils are improving the products upon drying.

OK, so this case fascinated me a great deal. I have previously learned a lot on film forming properties, oxygen barrier properties and other related topics to this in the past. But recently I learned that the properties from microfibrillated cellulose and cellulose fibrils is starting to show potential in art preservation or conservation. But how does this take place, and what’s the main functionalities behind all this? I spent some time researching the subject, and today I am sharing my findings with you. Some key words: stability, transparency and mechanical strength. Dig in to learn more!

It is important for producers of coatings to control flow and stability. The way to do this in water borne systems has typically been a work for synthetically derived additives, water-soluble cellulose derivatives or clays. Can cellulose fibrils do anything new for you?

Continuously following the world of cellulose fibrils and the development is both dynamic and interesting. A lot of new inventions are taking place, based on the cellulose fibrils. We have given 3D printing a quite high focus in the last couple of reviews, but this week there are two other news items on the list: composites made from cellulose fibrils. Dig into this week’s research review to find out more on what might possibly be the next generation of composite materials.

The performance coatings sector has seen decades of development to protect installations and transportation equipment. The sector has been highly dominated by solvent based systems and these systems have seen incremental innovations for a long period of time.

Never heard of Cellulose Fibrils, like microfibrillated cellulose (often referred to as nanocellulose)? Don't worry, I will guide you through the things you need to know. It is a completely new additive made from natural raw materials, designed to provide yield stress, shear thinning, stability and barrier improvements. It is the natural alternative to outperform current oil-based technologies. I will during this article give you a quick overview of what cellulose fibrils, using the example of Exilva microfibrillated cellulose, is and how it can benefit you.

Subscribe to our newsletter

Stay up to date with the latest from The Exilva Blog and receive the latest news straight to your inbox.