Water based waterproofing elastomeric coatings, especially roof coatings, have become a hot topic lately. One reason for this is that they reduce the heat absorption of the buildings when compared to the traditional asphalt roofs. In addition to heat prevention and energy savings, waterproofing coatings protect the underlying surface from water, UV radiation, chemicals, and deterioration.

Recent awareness in sustainability as well as changes in the legislation regarding single-use products, has put significant pressure on the whole packaging industry. Although fiber-based packaging is regarded as the solution for replacing plastic, the current solutions have big challenges regarding, for example, the recyclability.

High-build coatings, also known as ultra high-build (UHB) coatings are paints that are applied in high wet film thickness ranging from 5 Mils to 60 plus Mils. UHB coatings are typically used in situations where long term protection is needed or the material coated is exposed to harsh conditions, ranging from heavy rain to salt water. These coatings are preferably applied in one coat to save cost, especially in more demanding environments, such as in the case of bridges or high buildings.

There is a strong need to disinfect and sanitize frequently touched surfaces. Exilva Microfibrillated cellulose (MFC) is a biobased structuring agent that can thicken household disinfectant and cleaning products at low to high pH, as well as with oxidizing compounds.

There is a growing interest to increase the portion of bio-based components in various consumables. We have previously discussed about the challenges to incorporate microfibrillated cellulose (MFC) into composite materials with hydrophobic matrixes, such as PLA. Today we will take a step even further and see how cellulose fibrils can support the development of more environmentally friendly tires with high performance and durability.

You may have read about the issues related to lithium-ion batteries lately. Situations where the batteries have swelled or even caused a fire or an explosion. The question is, could cellulose fibrils be used to prevent these issues? Or would there be other functions in the batteries where the fibrils would be useful or even open new opportunities?

Nanocellulose has been a hot topic for several years and numerous applications have been proposed, some of them more potential than the others. The major limitation for the wider use of nanocellulose has been the limited commercial availability. The term nanocellulose, however, covers several different types of nano- and microfibrillated and fibrillar cellulose products. One of those is bacterial cellulose which is also more commonly referred as bio-cellulose. It might come as a surprise for many of us, but bio-cellulose is in fact present in several commercially available products. One of those were the legendary Sony MDR-R10 headphones which were introduced already as early as 1988.

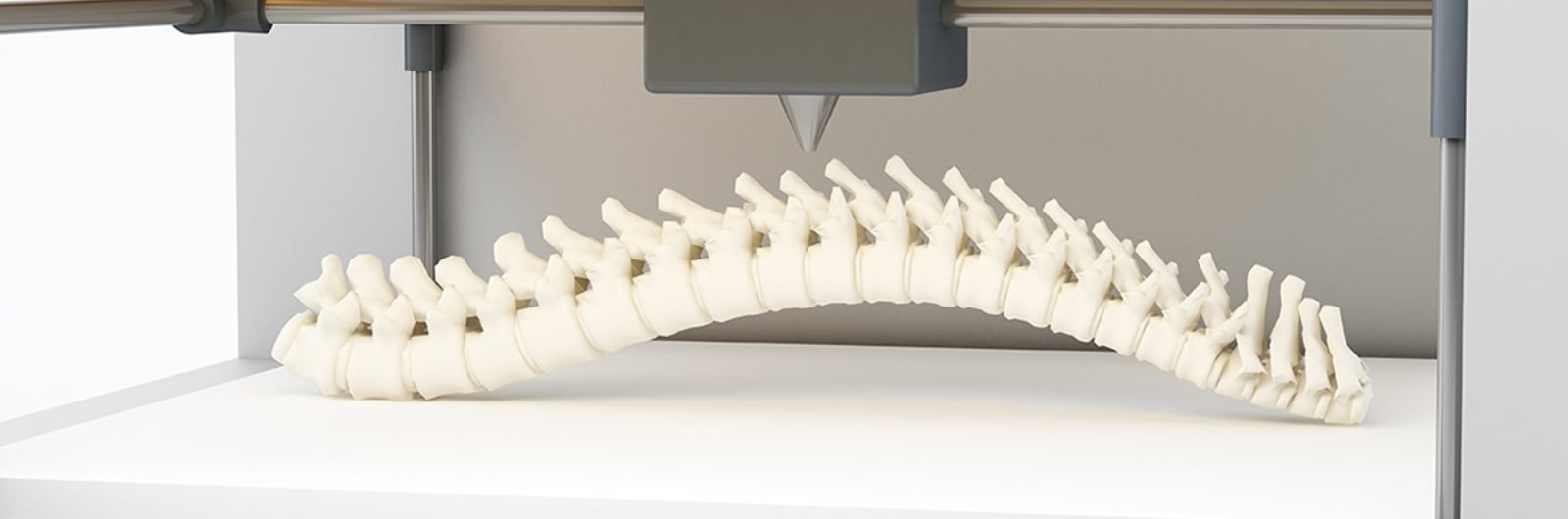

If you google the word medical device, you will get pictures of sophisticated hospital equipment and diagnostic devices. In practice, a term medical device is wider than just that and covers a range of different kinds of articles, starting from plasters and bandages to endosseous implants and implantable pacemakers, intended to be used for therapeutic purposes of humans or animals. We have previously written about the role of MFC in wound care products and today we are going to take a step deeper to the current status of nanocellulose in medical devices, especially topical and implantable ones.

You might have noticed how the air quality around us is changing constantly. Do you remember the last time that you have filled your lungs with fresh and clean air? Every day we are exposed to pollutants in the air we breathe - chemicals as well as fine particles - whether we are staying outdoors or indoors. This problem not only affects the people in developing countries, but the majority of the population on Earth.