Dispersion of Microfibrillated cellulose – a critical success factor

Ole Martin Kristiansen | November 7, 2017

Traveling around talking about microfibrillated cellulose for the past 8 years, has thought me an important lesson; always make sure that people understand how to disperse the fibrils sufficiently. This is really the main factor in gaining the key functionalities from the product. So how can you make sure that you are getting the most out of the cellulose fibrils when you are using it in your formulation? In this article I will give you some guidance and video tool on to how to get this right from the start.

Why is it important to disperse MFC correctly?

Please take note of the following: cellulose fibrils consists of an entangled and flexible three dimensional network. This means that it cannot be dissolved in a formulation like a typical water soluble polymer, but needs to be dispersed. These cellulose fibrils have a high affinity for water and also for each other. It has a high surface area and a high water holding capacity, meaning that strong gels are formed even at low concentrations in water.

When diluted in water or incorporated into a formulation, the strong network has to be disrupted so that the fibrils can interact with the new surrounding medium and form a new network structure.

When you achieve this fine homogeneous dispersion of the cellulose fibrils throughout your formulation, you obtain the strong network structure that gives you all the interesting properties the product has to offer.

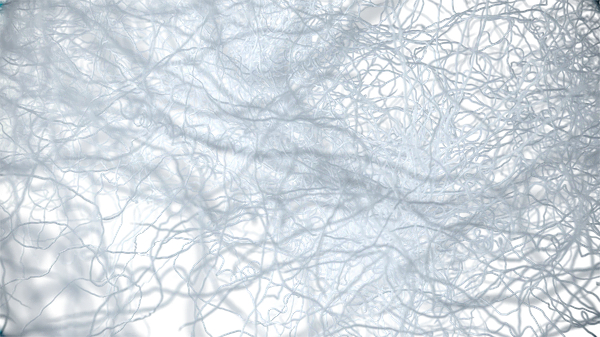

The three-dimensional network of the cellulose fibrils, illustrated in 3D.

So, how can I best activate cellulose fibrils?

There are several ways of achieving a good dispersion depending on the type of formulation and the equipment that you have available.

Some of the most important things to consider:

- When adding cellulose fibrils into a formulation, it can be a good idea to:

- Add it to the most polar phase of your formulation, preferably in the water phase

- Add it early in the formulation process, for example in the grind phase with pigments and fillers

- Ensure that the whole dispersion volume is homogeneously mixed and that you have an efficient transfer of the energy from the stirrer to the full volume of the dispersion

- It is a robust material and can be added in a homogenizing or milling step. If you have a process step that could help the dispersion, it is wise to add it before, or in, these steps.

- In an emulsion, the fibrils should be added to the water phase before mixing with the oil phase

- If you are diluting to a very low concentration, in a low viscosity medium, you might need high shear equipment. It might also be a good idea to make a more concentrated dispersion and dilute afterwards

- The higher the dry content of the cellulose fibril, the more energy and high shear will be required in order to disperse it properly.

Animation of low shear vs. high shear dispersion of Borregaards Exilva product.

Here is my advice on equipment and time

When dispersing cellulose fibrils, it is preferable to use high shear equipment. Lower shear equipment can also be used, but it takes longer to achieve sufficient dispersion (dispersion is a function of both time and shear force).

Below is a list of examples of equipment and dispersing times based upon our experiences.

| Equipment | Stirring speed (rpm) | Time (min) |

| Ultra-Turrax | 10 000 | 4 |

| Dispermat dissolver | 2 000 | 10 |

| Propeller mixer | 2 000 | 15 |

| IKA-stirrer (3 blade mixer) | 750 | 20 |

How to evaluate the quality of the dispersion?

When you are evaluating the incorporation into your formulation, you should look for a homogeneous dispersion that does not contain any lumps or visible aggregates. The cellulose fibril gives a very smooth and cream-like dispersion. Immediate sedimentation or phase separation might also indicate insufficient dispersion (like you see in the animation presented above).

Exilva MFC from Borregaard, as a 2 % dry matter.

A general advice when you do not obtain the expected effect in your formulations, is to examine the dispersion method and order of which the ingredients are added. If you suspect there is a problem with the dispersion, it might be a good idea to test different dispersion times and methods and see if this makes a difference.

The take-home message is that when using cellulose fibrils in your formulations, it is very important to notice that good dispersion is a critical factor for success.

Editor's note: This post was originally published in April 2016 and written by Marianne Rosenberg Read. We've revamped and updated it for accuracy and comprehensiveness.