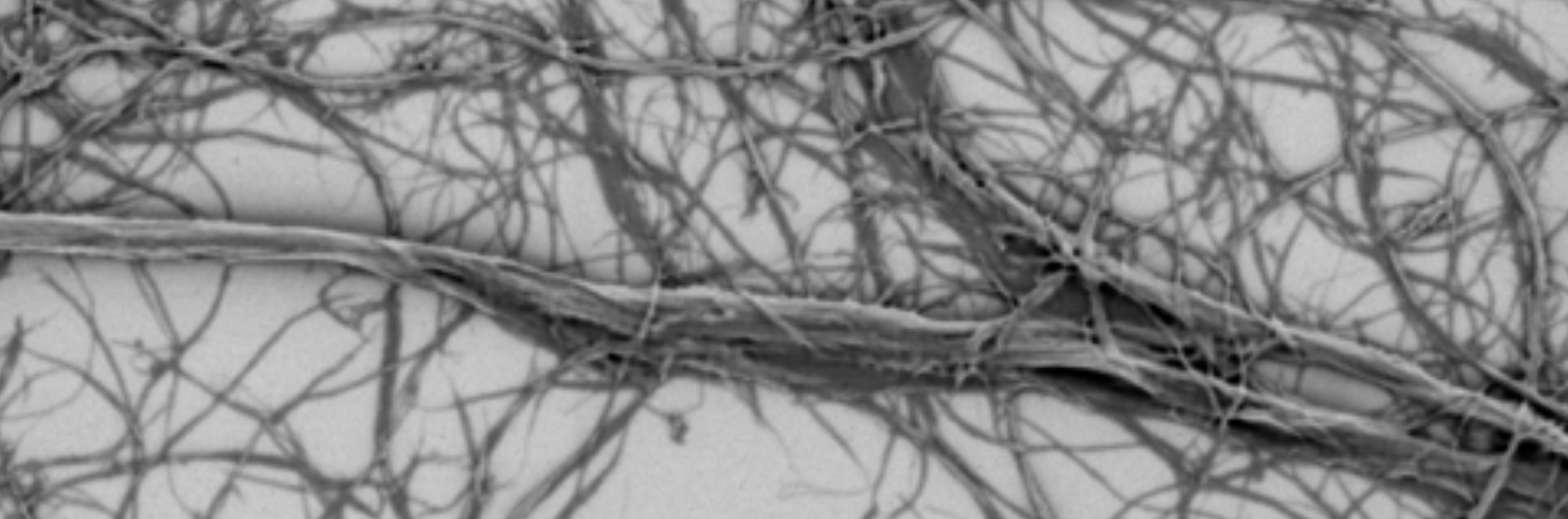

Cellulose fibrils have been written and talked about for years. A substantial amount of reports have been written prospecting all sorts of application areas. Based on its functionalities, it seems to be a good rheology modifier, a good stabilizer and it is showing substantial strength enhancement. But is there any proof to the pudding and where do we find the latest developments? I have tried to gather a couple of relevant examples for you, which to me are fairly new developments. Dig into this week’s blog post to find out what they are!

Shotcrete is concrete or mortar pneumatically projected at high velocity through a nozzle. Its components are aggregates, cement and water, and it can be complemented by fine materials, chemical additives and reinforcing fibers. Shotcrete can be applied with mechanized equipment or manually, using wet-mix or dry-mix spraying. The choice of the spraying method depends on the dimensions of the project, the quantity of concrete to be applied, as well as the logistical and environmental circumstances. Some important properties of shotcrete are the appropriate consistency and early strength development in its fresh state as well as compressive strength and durability in its hardened state. Let´s discuss some basic properties and functionalities.

Cellulose-based materials, like paper and board, are commonly used in packaging. They are light-weight, durable, bio-based and easily recyclable which have made them a popular packaging material. However, paper and board lack the necessary barrier properties for food packaging and therefore an additional barrier layer is often added on the paper. Today, this layer is made from polymers, like polyethylene terephthalate or polyethylene, or aluminium. There are efforts to replace these materials with bio-based, biodegradable films in order to reduce the dependency on crude oil as well as reduce the impact on the environment.

Our blog post of the week is today a really exciting one! We have been so fortunate to interview Peter Küker, who is a technical manager at Covestro in Germany. Peter has been working with cellulose fibrils in a project at Covestro for some time, and today he is sharing his views and experience on utilizing the fibrils in some of the Covestro formulations for adhesives. Don't miss out on this opportunity to learn more about the actual experience of utilizing the effect from the fibrils on rheology, dispersion and material handling.

Controlling rheology in very acidic or alkaline environments can be a tricky challenge. Different products ranging from examples like concrete to, your household cleaning products, are very different on pH. Extreme pH conditions can decrease the efficiency and functionality of some rheology additives, but there are some available alternatives. This post will try to give you some ideas on how the technology of cellulose fibrils can interact in your formulation and make sure you stay in control over your product´s rheology under difficult circumstances. And why is this ability from the cellulose giving you this benefit?

Bio-based is on everyone's lips these days, and there are a high number of initiatives going on in innovating new product systems with a bio-based background. In this post I will give you a sneak peak into the improvement of an organic solvent system, using a biobased additive as an example. Cellulose fibrils is a green and environmentally friendly material that consists of a complex three dimensional network of cellulose microfibrils.

Are you looking for a new additive for controlling rheology? In this article if will give you an explanation of the typical and well known rheology additive, and the Exilva Microfibrillated cellulose.

Ever heard about bouligand structures or tunicates? And how are these topics relating to nanocellulose? This week’s research review is giving you a summary of some really exciting news relating to strength performance from nanocellulose (nanocrystalline cellulose). In addition, we are bringing you news on nanocellulose as an art-preservation aid. Spend 4 minutes and read through some really interesting updates.

One of my favourite characteristics of the cellulose fibrils is its behaviour when drying or involved in the drying process of a product system. I have learned through some of our conducted tests that cellulose fibrils can act in an interesting and often beneficial way towards obtaining desired end product characteristics. Most of the examples on how the fibrils influence the drying are related to coatings. I however believe that similar behavior is possible to observe in application areas where a tight control of dry-out properties is desired. Evaporation of solvents is often the main technique for drying in many applications. I will therefore focus my blog post this time on this specific drying technique. Let me share some very interesting insights into why cellulose fibrils are improving the products upon drying.

Subscribe to our newsletter

Stay up to date with the latest from The Exilva Blog and receive the latest news straight to your inbox.