Sharper inkjet images without nozzle clogging

Otto Soidinsalo | May 16, 2017

Have you ever had problems with your inkjet printer? I bet that several people have experienced that during the years. The typical pattern is as follows: Your printer has been lying unused on your desk for weeks when suddenly you have an urgent need to print something. Often the outcome is that either the printing is messy or you end up having a blank paper in your hand. This is usually due to the drying of the ink on the printer head which is also known as nozzle clogging.

In the past, we have been discussing about the water holding capacity of microfibrillated cellulose (MFC) as well as bout its unique rheological properties, compatibility with surfactants and about its excellent stability as well as stabilizing properties. Today we will discuss how MFC can help you to develop better inks for inkjet printers and even help you to print sharper pictures.

Inkjet printing

Inkjet printing is a type of computer printing that creates an image by ejecting droplets of ink onto paper, plastic or other substrates. Inkjet printers are the most commonly used type of printers and range from small inexpensive consumer models to expensive professional machines. Most consumer inkjet printers use the thermal inkjet process, in which the ink droplet is ejected from the printer head by the pressure created by evaporating solvent. The typical inks used in thermal inkjet printers consist of water, glycols, alcohols, dyes or pigments, and resins/polymers as the main ingredients.

They may also contain surfactants, defoamers and preservatives. Polymers are mainly added to the inks to control the viscosity and, in the case of pigments, to stabilize them. In addition, they work as humectants. Several types of polymers are used, both natural and synthetic ones, such as xanthan, cellulose ethers, acrylates, polyvinyl alcohol and polyethylene glycol.

Another important component in inkjet printing is the paper. There are several different qualities available, starting from basic uncoated paper to high gloss photo papers, intended for printing pictures. The basic requirements for the paper are: good ink absorbency, fast drying of the absorbed ink and good water resistance. The photo papers are usually formed from several layers, made by lamination and highly refined clay is commonly used to prevent ink spreading.

Challenges related to inkjet printing

The main challenge related to inkjet inks, especially used in thermal inkjet process, is the drying of the ink to the nozzle, leading to nozzle blocking. Also the general stability of the inks, including settling of the pigments, is sometimes challenging. On the other hand, the main challenge related to the printing itself is the bleeding of the ink during printing. It is mainly related to the material that is printed on but also the ink formulation has its own effect. The bleeding of the ink leads to messy, unsharp pictures.

MFC in ink and printing

MFC has some properties which could be beneficial for printing applications, such as, water holding capacity, high tolerance for ionic compounds and the ability to prevent agglomeration of pigments and precipitation of dyes. MFC can also help to increases the adhesion of the ink to the paper and even effect positively to the water resistance by tightly binding the pigments on the substrate. Lately, Ooi et al. reported how small addition of cellulose nanofibers suppress the coffee-ring effect during drying of colloidal suspensions on solid substrate. The inhibition of coffee-ring effect enables not only to print sharper pictures but also to get more uniform and smooth coating in general.

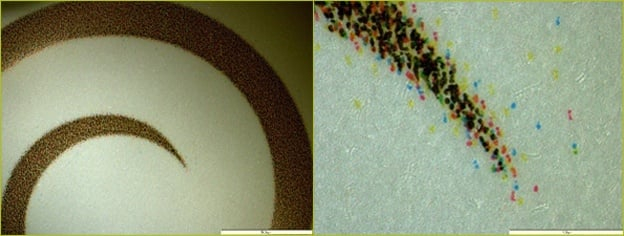

On the other hand, in inkjet papers, especially on those which are targeted for printing high quality pictures, MFC could be used in the ink receiving layer. The following pictures demonstrate the printability of MFC film and its ability to prevent the bleeding of the ink. The prevention of spreading/bleeding of ink is especially important when printing high quality pictures such as photographs. In addition, the good barrier properties of MFC can increases the gas resistance of the paper which might decrease the fading of the colors during storage.

Microscopic pictures of MFC film with 30% sorbitol (film produced by Technical Research Centre of Finland), printed by using inkjet printer (HP OfficeJetPro 8720). 63x magnification on the right.

Future

The future will tell if and when MFC will take us closer to more durable inkjet printers or allow us to print even sharper pictures or in best case do both. Maybe this will be another example of the multifunctionality of MFC. In any case, it is definitely another exciting application that I’m sure that we will hear more from in the near future.

Written by:

Otto Soidinsalo

Dr. Otto Soidinsalo holds a Ph.D. in organic chemistry from the University of Helsinki. Currently he works as a Technical Application Manager at Borregaard. Before joining Borregaard, Otto was working in various positions in pharma and cellulose derivatives related industries for 8 years, ranging from R&D to product and application development and technical services. Currently Otto is focusing on CASE as well as on paper & packaging applications, especially on barrier coatings. Otto possesses a deep understanding of the natural polymers and their derivatives and their impact on rheology as well as mechanical properties of various applications.