How to compare rheology additives: The example of nanocellulose/cellulose fibrils and HASE

Ole Martin Kristiansen | October 23, 2018

For decades, producers of fluid materials have used HASE as the fundamental technology to control flow. How can new technologies complement this work horse of rheology modification? This week I am trying to uncover the key aspects of the HASE technology and give you ideas on the HASE technology in relation to the world I am familiar with: nanocellulose and cellulose fibrils.

What is hase?

Hydrphobically modified alkali swellable emulsions (HASE), are rheology additives delivered at low pH, and needs increase in pH to start their thickening effect. In addition, it has hydrophobic groups which can associate with each other. In this process they form micelles which enables attachments with the hydrophilic part of the formulation. This is making it a versatile and important rheology additives. Below, I have tried to compare it to the technology I know, nanocellulose/cellulose fibrils and how these two technologies affects the rheology of your formulation.

Similarities and differences

The first and most striking difference between the two additives is their physical and chemical nature. HASE, a water-soluble polymer, is a synthetically derived product with various product types based on its molecular composition (weight and chain length). It is, as the name suggests, swellable only in alkali environments.

The nanocellulose/cellulose fibrils is an insoluble fiber network not dependent on the same alkali environments to work. Its effect on rheology and thickening varies across the pH ranges but is stable from pH 1-13 (source: Borregaards Exilva product).

→ Read also: What makes cellulose fibrils stable over a wide PH-range

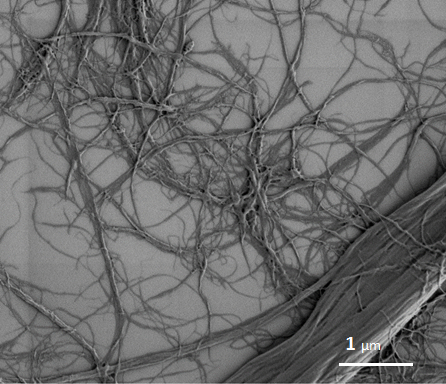

Cellulose fibrils (Borregaard's Exilva MFC) seen in microscopy.

The insoluble fibrils can be seen in the picture.

The degree of shear thinning of nanocellulose/cellulose fibrils and HASE can also be slightly different. This difference in rheological properties is relevant for time delay in viscosity recovery (thixotropy). In certain applications, it might be a good option to combine HASE and cellulose fibrils to achieve a desirable rheology profile (fine-tuning the shear thinning and thixotropy. Nanocellulose/cellulose fibrils can also boost the effect on open-time, anti-cracking and emulsion stability, providing a good synergistic effect with the HASE’s rheology control.

Addition: pre-addition and post-addition

HASE and nanocellulose/cellulose fibrils are different in material handling and introduction to your product formulation. HASE is a technology which is famous for its ability to fine tune the properties of, for instance coatings, at the end of the manufacturing process. This is due to its low viscosity and how alkali environments activates its thickening properties. Nanocellulose/cellulose fibrils can also be post-added, but is more vulnerable to the need for high shear to be present (see our blog post on the subject). A manufacturer of coatings should rather add nanocellulose/cellulose fibrils in the grinding phase to ensure the necessary shear.